On average injection molded parts should have a wall thickness that. Browse reconditioned DC motor listings.

Micro Injection Molding Machine Plastic Injection Molding Injection Machine Plastic Injection

Based on the part that was molded estimate or measure the amount of plastic resin needed to be mixed here is a 11 mix.

. I dont understand the point of DIY injection molding. DIY Injection Molding Step by Step 1. Thus we refer to it as an injection molding attachment for a drill press.

First pick the CAD software tool of your preference to design the mold insert. Snap joints should have a thickness of 05 times the. Both Injection Molding and Computer Controlled Numeric Machining are methods that can be employed by many industries and project teams to design a product.

Then I was able to make copies of that item using a home plastic injection molding. Two little blocks of 6061 aluminum make up the halves of the mold. Read on to see the best DIY and desktop injection molding machines.

Find various sizesbrands like Siemens GE more. Interesting homemade tool from Instructables user Random_Canadian. Its very affordable and students are able to learn the principles of injection molding.

The melt chamber consists of a length of 34 iron pipe the piston head is an off-the-shelf socket. I made an epoxy mold of an existing plastic item. First two 0124 holes are drilled through both blocks to hold guide pins that will ensure the mold halves.

Motorized powered drift trike go kart tricycle PLANS Diy build your own. Connect with sellers directly. Browse reconditioned DC motor listings.

Injection molding is the process of injecting molten material such as plastic or metal into a mold to make an item. Injection molding auxiliary equipment. You can make reasonable molds with hand tools using some old techniques.

Connect with sellers directly. Ad Leading marketplace for used DC motors. A new online marketplace called Bazar sells products made with the machines in an attempt to help more people begin to make a living by recycling plastic.

A hopper is located at one end of the barrel. Find various sizesbrands like Siemens GE more. Be sure you will get the best out of more than 4000 used machines and tools.

The unit itself measures approximately 12 inches long x 1-34 inch diameter at its widest point and weighs just 3. Its often used for creating prototypes or for mass. Be sure to check out the newest version of the machine called the MK3 herehttpsyoutubehw4NI60WW8IThis video will show you how to build your own.

The structure of an injection molding machine can be briefly summarized as consisting of an injection unit that sends the melted materials into the mold and a clamping unit that operates. Ad Shibaura Offers All-Electric Servo-Hydraulic Injection Molding Machines Solutions. Ad At Surplex you will find used machinery and industry equipment at best prices.

Preliminary 2D and 3D design models are constructed to determine mold sides and steel sizes. Scraping and Shaping is one of the oldest. Once these are reviewed and approved the detailed.

You dont need a CNC machine to make molds. First a draft angle needs to be added in case of snap joints. Design the Mold in CAD.

Well use the open-source Blender but the workflow. The video on the Action Box channel on Youtube describes the step-by-step process for building the Injekto molding machine with the operative word being simplicity. This means shorter cycle times resulting in more parts produced per hour and lower production cost.

Injection molding machine consists of a barrel cylindrical pipe. 1800 for the 150A. We Have Extensive In-House Capabilities For Precisions Quality Plastic Injection Molding.

Ad Leading marketplace for used DC motors. Place the side with the sprue and air holes face up. A hydraulic ram or rotating screw runs by electric motor used.

In the case of crush ribs however a draft angle is not needed. The central material dryinghandling system including five insulated drying hoppers dehumidifying dryer pumps filters and. Clamping force as a function of surface area.

Mold manufacturing and injection service are so cheap about 2k for mold about 1 per part for reasonably sized and. Home Plastic Injection Molding With an Epoxy Mold. What his customers love about the tabletop machine is the price.

Ad Premium Manufacturing Capabilities For In-house Stamping Injection Molding Assembly. Injection Molding SIZING AN INJECTION MOLDING MACHINE Packing pressure 108Pa Clamping force F PA Figure 7.

Homemade Plastic Injection Molding Machine Plastic Injection Plastic Injection Moulding Machine Diy Molding

Solidworks Hydraulic Injection Molding Machine Injection Machine Plastic Injection Molding Injection Moulding

Make Your Own Injection Molding Machine Make Diy Molding Plastic Injection Molding Molding

Pin On Proyectos Que Debo Intentar

Homemade Plastic Injection Molding Machine Pdf Ftempo Inspiration Plastic Injection Molding Plastic Injection Plastic Injection Moulding Machine

Plastic Injection Moulding Machine Model 4 Plastic Injection Molding Plastic Injection Plastic Injection Moulding Machine

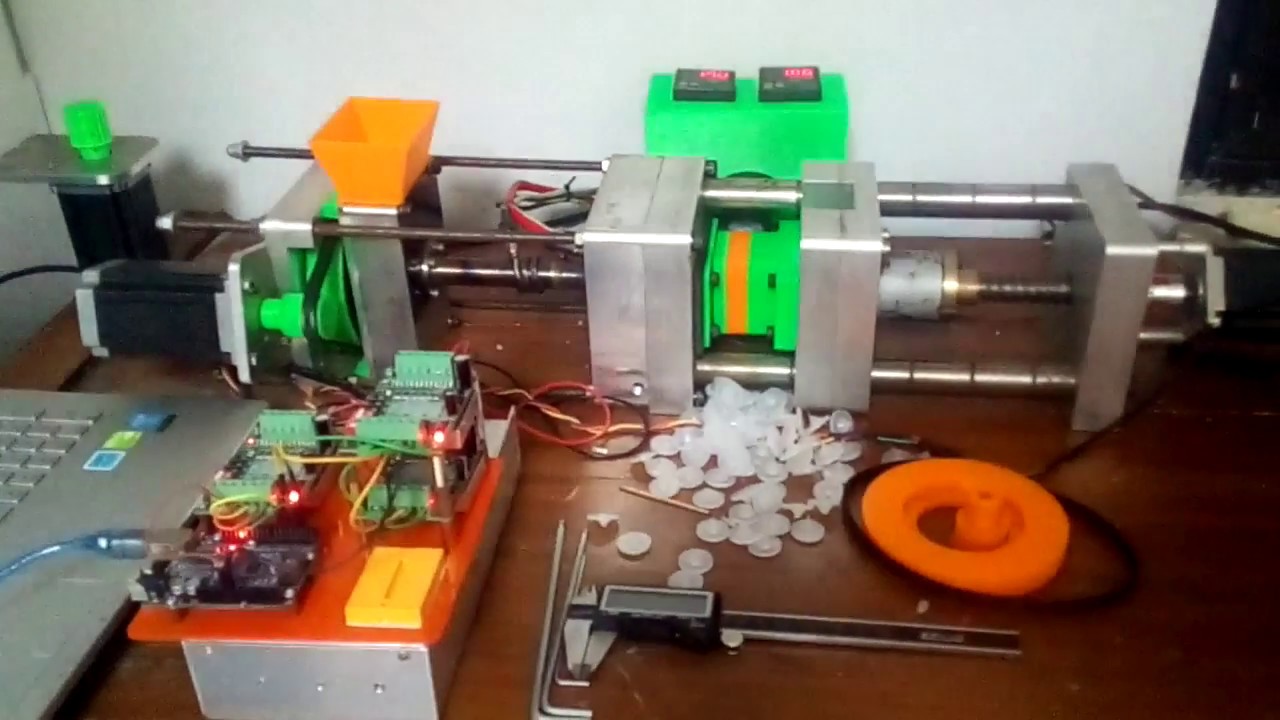

Desktop Injection Support By 3d Printed Controlled By Arduino Uno Youtube Arduino Plastic Injection Plastic Injection Molding

Home Injection Molding Diy Molding Injection Moulding Injection Machine

Make Your Own Injection Molding Machine Make Plastic Moulding Diy Molding Metal Working Projects

Injection Molding Machine By Scorch Homemade Plastic Injection Molding Machin Plastic Injection Moulding Machine Plastic Injection Molding Plastic Injection

Model 150a Plastic Injection Machine Injection Machine Plastic Injection Plastic Moulding

Desktop Injection Molding Machine Get Inquiries 56 Youtube Injection Machine Plastic Injection Molding Plastic Moulding

Plastic Injection Machine Injection Machine Injection Moulding Process Plastic Injection

Diy Injection Molding Plastic Injection Molding Injection Moulding Plastic Injection

Make Your Own Injection Molding Machine Make Diy Molding Diy Projects Homemade Machine

Pin By Arbi Oussama On Car Lights Plastic Injection Moulding Machine Plastic Injection Molding Diy Molding

Microplast Hot End Youtube Plastic Injection Molding Plastic Design Plastic Injection Moulding Machine